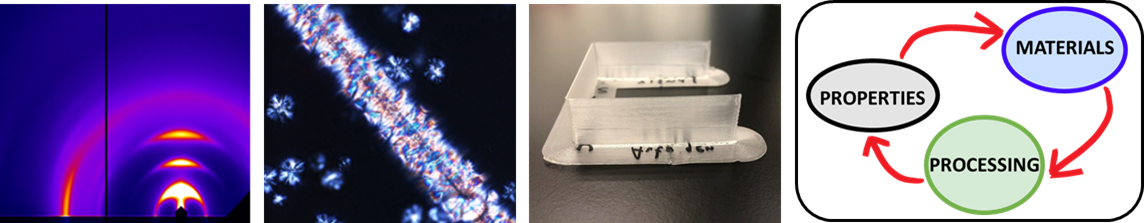

The objective of our work is to address growing technological needs and societal problems by understanding and controlling the fundamental mechanism of crystallization of polymers during processing. The specific morphology that develops during manufacturing dictates the final material properties, so it is crucial to attain control over the type of structure that develops during processing. In our group, we explore the complex interplay between molecular structure, processing conditions, structure development and resulting properties of polymers to enable rational design of material and processes for a particular application.

The range of current and potential applications for semicrystalline polymers is extremely diverse, including biomedical devices and implants, solar cells, transistors, film packaging, high-pressure gas piping, high-performance fibers, and structural components, among others. We are particularly interested in ultimately improving quality of life by enabling the design of advanced semicrystalline materials that can positively impact biomedical devices, energy harvesting, and functional materials.

Research Areas

CONDUCTING POLYMERS FOR ENERGY APPLICATIONS

Conjugated polymers are capable of charge transport and thus candidates as active layers for solar cells, flexible electronics, sensors, transistors, and light-emitting diodes. The semicrystalline structure of conjugated polymers dictates final transport properties, but controlling crystallization during processing remains a critical challenge. In our group, we investigate the fundamentals of conjugated polymer crystallization and use this knowledge to direct structure formation. Our ultimate goal is to attain optimal final properties suitable for energy applications.

Highlight: “Direct observation of two-step, stratified crystallization and morphology in conjugated polymers” in Macromolecules, featured in the Front Cover. See the UNL press release here.

LIFE CYCLE OF POLYMERS

Our group is working to address sustainability and environmental considerations critical to the use of polymers. Our focus is on: 1) examining and addressing the release of polymer micro- and nanoparticles during use of consumer plastic products, 2) processing of biosourced materials (biopolymers) to attain optimal final morphology and properties, and 3) optimizing properties of recycled or upcycled materials through molecular characteristics and processing conditions.

Highlight: “Assessing the Release of Microplastics and Nanoplastics from Plastic Containers and Reusable Food Pouches: Implications for Human Health” in Environmental Science & Technology, featured as a Research Highlight in Nature (https://www.nature.com/articles/d41586-023-02091-w. See the UNL press release here.

FLOW INDUCED CRYSTALLIZATION

Strong flows are typically applied onto polymer melts during traditional processing (injection molding, blow molding, fiber spinning, etc). Flow significantly impacts the crystalline orientation/kinetics and can dramatically alter final properties, but flow-induced crystallization and its relationship to molecular characteristics and processing conditions is still not fully understood. We use model polymers and custom-designed processes to investigate flow-induced crystallization to work towards a predictive model.

3D-PRINTING

3D printing is powerful polymer processing technique with outstanding flexibility for manufacturing complex geometries. However, quality is often subpar due to warping and lack of cohesiveness, especially for semicrystalline polymers. In our lab, we investigate the relationship between materials, processing, and crystallization which dictate final morphology and properties of the printed objects. Our goal of this research is to expand 3D-printing beyond prototyping and to increase the range of suitable materials.

Experimental techniques

We are an experimental group and employ a range of characterization techniques, both ex-situ to examine final morphology and in-situ to investigate structure formation in real-time. Some of the experimental techniques we typically use are differential scanning calorimetry, polarized optical microscopy, birefringence and turbidity measurements, uv-vis absorption, fluorescence, mechanical testing, and synchrotron-based X-ray scattering (WAXD/SAXS/GIWAXS) and reflectivity.

Funding

- National Science Foundation

- Nebraska Center for Energy Sciences Research

- Research Council, University of Nebraska at Lincoln

- Collaborative Initiative - University of Nebraska at Lincoln

- Woollam Foundation